Aqualis Composite Wood Product FAQs

What is Wood Plastic Composite?

Composite Wood is the product of combining up to 90% recycled wood fiber, plastic (Traditionally PVC) and filler material, in some cases with some type of binding agent and in others without added binder . The resulting ‘Wood Plastic Composite looks very much like natural wood. WPC Composite is a very versatile product and is used in flooring, furniture, retaining walls and so on infact working with WPC composite is very much like working with natural wood. Generally, composites have the added benefit of being less likely to split, delaminate or be attacked by termites. Composite Wood can also be engineered to be lighter weight for easier handling and have a fire rating.

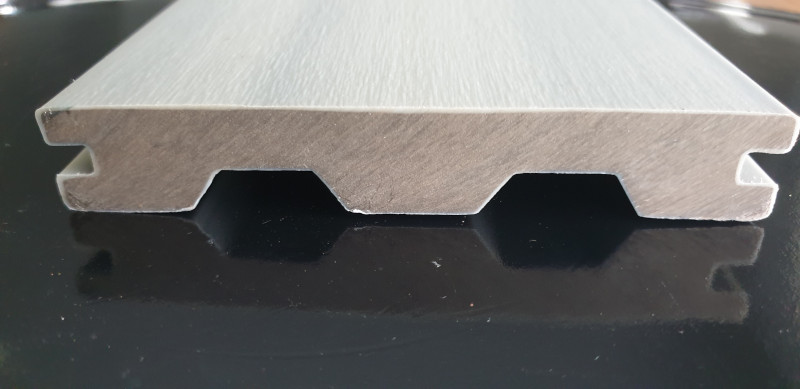

What is Capped Stock Composite?

Capped Composite is made from up to 90% recycled materials. Its structure comprises of a composite inner core (mostly wood pulp and plastic) which is co-extruded with an outer polymer capped shell. The ‘Capped Stock’ outer core polymer used can very between brands predominantly polypropylene and high-density polyethylene (HDPE) are used. The performance claims made by individual manufacturers is basically dependent on the polymer type used on the outer shell, generally it is touted as having better wear properties, improved UV resistance, stain resistant and structurally more stable than conventional WPC Composites.

My composite should be maintenance free, is it?

Although many composites are formulated to be fade, scratch, and stain resistant, the individual constituents of the composite are not immune to the effects of the harsh Australian climate and extremes of heat, water, and high levels of UV radiation. Wood-plastic composition can be susceptible to UV degradation from exposure to sunlight, swelling due to absorption of water through cut ends, wearing out in high trafficable areas, excessive expansion, and contraction due to extreme temperature fluctuations, can become slippery, just like timber will retain pollutants such as tree sap dust and dirt from the environment. Principle raw materials used to make composites such as, wood pulp and binders, are also prone to weathering, and attack from bacteria, fungus, mould etc. therefore, although composite wood may be somewhat more resistant than other materials, it will still require some level of maintenance and up-keep. Our recommendation is to wash/condition the composite with Aqualis Composite Bright (refer to label instructions) and seal with Aqualis Composite Sealer (refer to label instructions) to help protect and extend the serviceable life of WPC Composites.

Why is it important to occasionally clean my composite decking?

Like all floor surfaces, composites are not immune to build up of dirt and grime, food and drink stains, oil, microbial (mould and fungal) attack, residues from pollution, environmental surroundings which include tree sap, salt deposition in coastal areas, abrasion from sand, etc. It is important to keep these surfaces clean and free from such contaminants. The choice of cleaner is vital to ensure the surface of the composite is not compromised in any way, we recommend an intermittent wash with Aqualis Deck Bright (refer to label instructions).

Do I need to seal my Composite?

Composite Wood does not deteriorate like natural timber, it does not become grey but often fades to a washed-out shade of its original colour giving a plastic-like or synthetic appearance. The rate of deterioration will be subject to brand of composite used, geographical location, level of exterior exposure to weather elements such as sun wind and rain, level and frequency of foot traffic, degree of wear and tear due to abrasive materials such as sand and sea salt, time allowed for dirt and grime to lock in and concentrate microbial degradation and poor construction methods for example poor ventilation and so on. We recommend that wood plastic composites are sealed to extend life and maintain their original aesthetics. WPC Composites should be treated with Aqualis Composite Bright (refer to label instructions) and sealed with Aqualis Composite Sealer (refer to label instructions) to help protect and extend the serviceable life of WPC Composites.

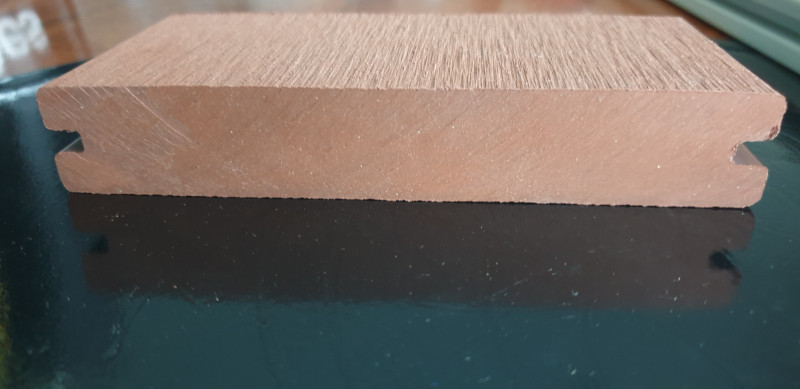

What type of composite do I have?

Generally there are two main types of composites used for decking in Australia, WPC Composite (Wood Plastic Composite) and Capped Composite (Capped Stock Composite).

WPC Composite is the product of combining up to 90 % recycled products which include wood fiber, plastic (traditionally PVC) and filler material, in some cases with some type of binding agent and in others without added binder. The resulting ‘Wood Plastic Composite’ is usually denser, stronger, and heavier than most common species of natural wood.

Capped Composite is also made from up to 90% recycled materials. Its structure comprises of a composite inner core which is co-extruded with an outer polymer capped shell. The ‘Capped Stock’ outer core polymer used can very between brands, Polypropylene and High-Density Polyethylene (HDPE) are amongst common types used.

Can my composite be sealed?

Before sealing your composite, it is important to identify what type of composite it is. WPC Composite or Capped Composite? (Refer to Aqualis Web site for more detail)

Yes, most WPC Composites (wood plastic composite) can be sealed simply by washing/treating the surface with Aqualis Composite Bright (follow label instructions) then sealing with Aqualis Composite Sealer (follow label instructions).

No, most Capped Composites cannot be sealed due to the chemistry of the encapsulating polymers used.

Please note however, with so many suppliers of composite flooring in the market, and the multitude of formulations in circulation, it’s always advised that pre-testing for adhesion be undertaken to ensure the desired product performance is achievable.

Can I seal Capped Composite?

No.

Adhesion of sealer to the Capped Composite depends on the polymer used for the encapsulating layer.

Most Capped Composites cannot be sealed because at present, commonly used encapsulating polymers are high density polypropylene (HDPE) and polypropylene both of which are notoriously difficult to achieve adhesion of any coating to.

Note, with so many suppliers of composite flooring in the market, and the multitude of formulations in circulation, it’s always advised that pre-testing for adhesion be undertaken to ensure the desired product performance is achievable.

My composite has faded badly, how can I restore it back to new?

Yes, faded WPC Composite can be successfully restored by wash/treating with Aqualis Composite Bright followed by colour restoration using Aqualis Refresh and finally sealing with Aqualis Composite Sealer. Ensure to follow all product guidelines for application requirements.

Can I wash stains off my composite using acetone, nail polish remover or paint thinners?

No.

Depending on the age of the composite and the degree of wear of the surface it can be quite difficult, and sometimes impossible to remove old stains without bleaching out the colour or irreparably damaging the composite.

Harsh industrial grade detergents, bleach or chemicals can damage the surface of the composite and what started off as a small stain can end up much worse. Never using High pressure water jet to blast dirt and stains off composite surfaces. Always ask the supplier of your composite what is recommended for removal of stains on their product.

It is advisable to remove stains as soon as possible to minimise long term damage.

We recommend using a diluted solution of Aqualis Deck Bright for general cleaning or a diluted solution of Aqualis Composite Bright (only suited for use on unsealed decks) for difficult stains.

We recommend sealing your composite using Aqualis Composite Sealer to minimise and avoid problem staining.

Can I remove old coatings or paint from my composite deck?

Yes, existing coatings or paint can be removed from composite decking using Aqualis Strip Ease, ensure to wear appropriate protective clothing including safety goggles. (Follow all label instructions always pre-test a small patch before progressing to larger areas working in small sections at a time).

Never use strong solvents like paint thinners, acetone, or industrial grade paint stripper as this can damage the surface of the composite. Do not try and sand or scrape the coating off as this will permanently damage the surface. Never use high pressure water jet to blast old paint or coatings off composite this can permanently damage the surface.

Can I sand my composite deck?

Yes, but with caution.

Sanding of composites, especially large areas should be done by trained professionals who are equipped with the appropriate equipment to avoid patchiness or irreparable damage to the surface. Small areas may be lightly sanded to enable repairs, but care must be taken not to over sand or overheat the composite surface.

My composite deck is overgrown with mould, lichen, and algae, how do I clean it? how do I stop it growing back?

Microbial growth occurs or is encouraged if there is a build-up of debris and organic matter from plants (foliage, fruit, bark etc.), accumulation of dirt, dust, phosphate pollutants from rain, poor drainage, poor ventilation, presence of high levels of moisture. If the surface is weathered and has become porous, fungal spores will become embedded and difficult to wash away or kill hence resulting in frequent mould bloom especially in areas subject to dampness and poor ventilation.

It is important to keep composites clean, wash as required using Aqualis Deck Bright. Once the surface has been thoroughly cleaned and is free from microbial growth, allow to dry out thoroughly then treat with Aqualis No Fungal Pro (follow label instructions). We recommend that once dry, weathered WPC Composite be sealed with Aqualis Composite Sealer making the surface impervious to water once again and resistant to mould growth.

My composite deck is prone to getting quite slippery especially when wet, what can I do to make it safer?

Wash treatment with Aqualis Composite Bright and allow to dry thoroughly. If colour restoration is required, restore colour using Aqualis Refresh and allow to dry overnight then apply three coats of Aqualis Traction to achieve either P4 or P5 slip rating. If no colour restoration is required apply three coats of Aqualis Traction directly to the wash treated surface.

Can I change the colour of my faded composite?

Faded WPC Composite can be either restored to original colour or changed if desired using Aqualis Refresh. Because Refresh is a transparent colourant, the original colour and degree of fade in the Composite will have an impact on the outcome. It is advisable to do a test sample ensuring the desired colour is achievable or contact Aqualis for technical advice.

What is Composite Sealer?

Composite Sealer is a water based polymeric emulsion designed to protect Wood Plastic Composites against food, oil staining and dirt retention whilst restoring water repellency. It is applied over correctly prepared WPC composite substrates, worked evenly over the entire surface with lamb’s wool applicator, squeegee mop, brush or roller and allowed to dry off. Composite Sealer is quick and easy to use and will enhance the beauty of the composite surface locking in pigmentation and slowing down the ageing process due to effects of water and UV exposure.

What is Composite Bright?

Composite Bright is a water-based composite surface cleaner/conditioner treatment for the application of Refresh (colour restoration) and Composite Sealer. Composite Bright is also suited as a general-purpose composite cleaner to be re-applied on unsealed composites as often as required to maintain a fresh, clean look of all composite decks, stairs, handrails, cladding, screening, furniture etc.

What is Traction?

Traction is a polymeric emulsion which has been designed to impart the natural look on WPC Composites substrates and delivers slip resistance. It is designed to provide a full slip resistance P4 rating as per AS/NZS 4586-2013, and with the addition of P5 Grit will give a full P5 rating as a wet surface pendulum test. Traction is quick and easy to use and can be used as a Sealer to protect the Composite surface or as part of the full protection/colour restoration process with Aqualis Refresh.

What is Refresh?

Refresh is a solvent based UV resistant stain designed for use on all internal and external wood and WPC composite surfaces. Refresh exhibits excellent application properties delivering natural looking colour with excellent transparency and light fastness.

How often do I need to seal my composite deck?

Durability of Composite Sealer is dependant on many external factors such as environment, degree of traffic, abrasive sand, etc. Sealed WPC Composites are quite durable. Like all trafficable surfaces monitoring for wear or coating failure is required. Re-coating is a simple Composite Bright wash and Composite Sealer re-coat. On average a sealed surface may last 2 – 5 years.